Business Card Holder - Design for Manufacturing

This past quarter, as a part of my manufacturing concentration, I completed a course in Design for Manufacturing and Assembly. In the lab section, we worked to create a business card holder using various manufacturing methods, designing the parts and the processes to make them. The holder consisted of a laser-cut sheet metal backing, an injection molded plastic insert, and a CNC machined base.

Machined Base

The base of the business card holder was CNC machined from a blank of aluminum. Not only did I redesign the base with machining in mind, but I also wrote the CAM for the part using the HSM Works add-in to SolidWorks, and ran it on a Haas VF2 CNC Machine. This was the first time I had designed a part, created the tool paths, and manufactured it myself! The part was then taken to a local vendor for powder coating.

Injection Molded Insert

The insert on the left of the holder was made using our injection molder on campus. While we used standard molds for this project for the sake of time and cost, we did have the opportunity to design our own using SolidWorks.

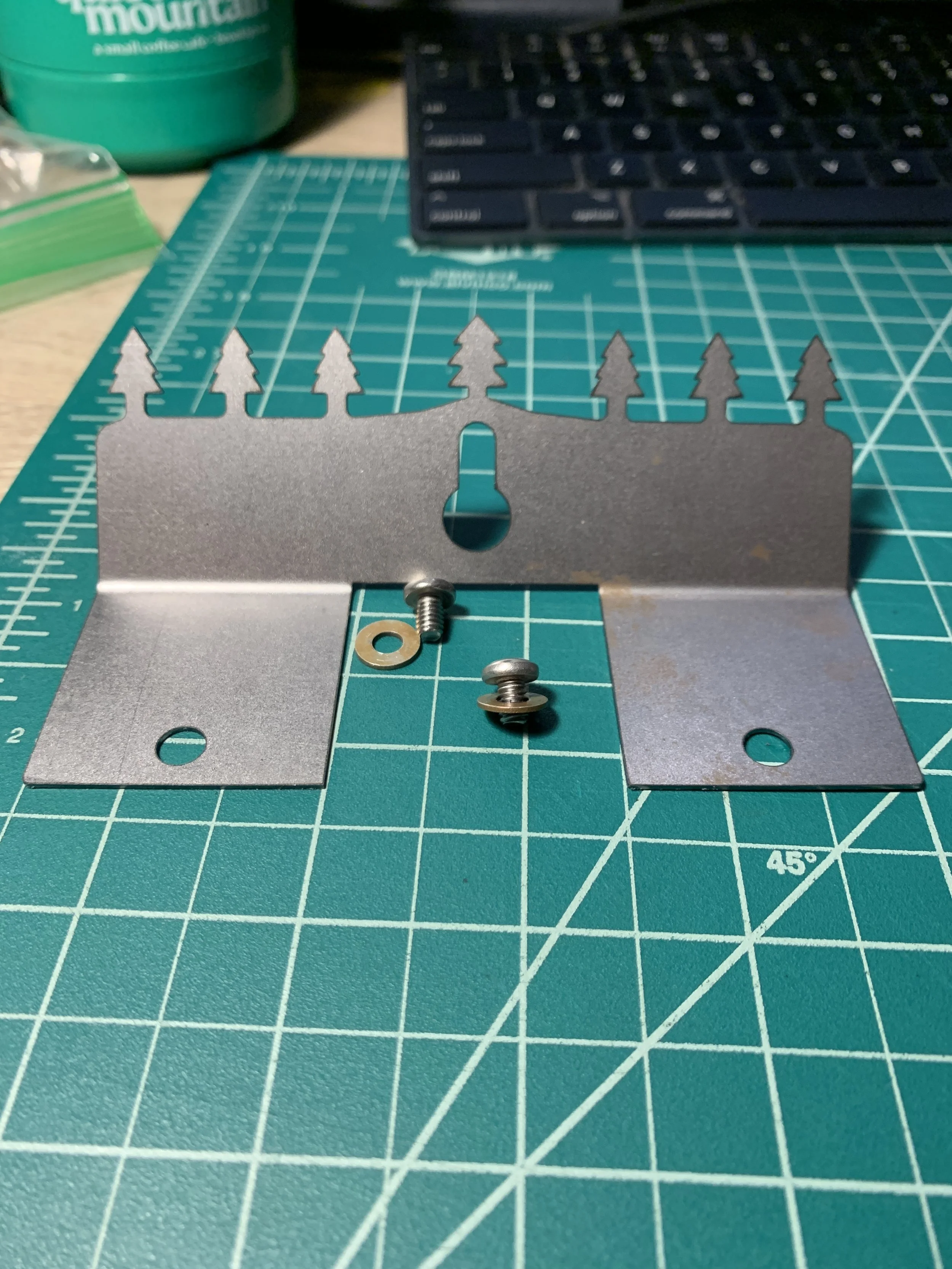

Laser-Cut Back

The backing of the holder was a laser-cut and bent sheet metal part. We had the opportunity to create the design on the top, for which, I went with a row of trees. The part also has features to mount the entire holder on a wall. With the design finished, we then programmed the tool paths in HSM Works, and made the parts using a campus laser cutter.