Injection Molded Screwdriver - Product Design

This quarter, in my capstone manufacturing course, Tooling and Fixture Design, we started the quarter with a deep dive into molded product design. This project encompassed detailed design of a molded screwdriver handle and all of the tooling required to manufacturer them. Looking back, it is absolutely the project I am most proud of, and I hope you enjoy reading the details below.

Product Design - Handle and Bit Holder

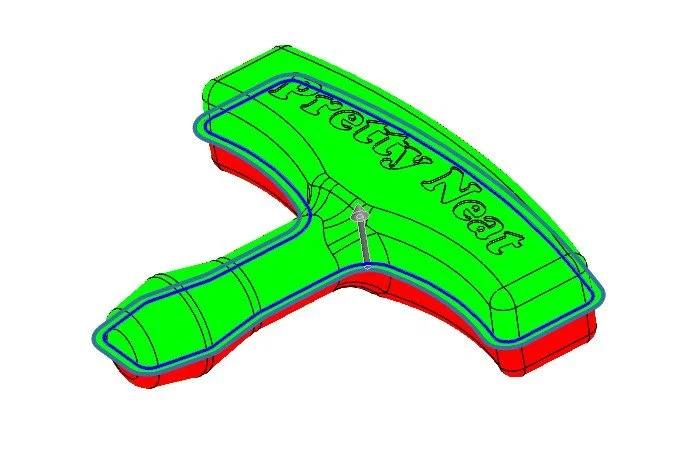

The lab instructor provided a standard Phillips screwdriver blade for us to design our handles for. I felt this was a bit boring, and wanted to make a product that was much more useful and versatile than a fixed Phillips blade. So, after doing some research, I settled on designing my handle to work with a Makita Impact-Rated Bit Holder. This holder can use any 1/4” Hex Bits, allowing for use with Phillips, Flat Heads, Torx, you name it. My goal was to create a handle that was ergonomic and aesthetically pleasing, and easily moldable. Below, you’ll see screenshots of the final handle in SolidWorks.

Mold Design

Designing the molds for this product was absolutely the crux of the project. Using the Mold Tools in SolidWorks, I designed the molds for the part, accounting for shrinkage and adding draft on vertical surfaces. I then added features to locate the two mold halves together with dowel pins, as well as mounting fixturing for the injection molding machine. Lastly, I added the sprue, runner, and gate necessary to inject. As the handle is overmolded onto the blade (the blade serves as a core), I also added a core print feature.

Mold CAM and Machining

After designing the molds, it was time to machine them. Using HSM Works within SolidWorks, I programmed all the tool paths required to machine the molds on the Haas VF2SS in the Advanced Manufacturing Lab on campus. I really enjoyed getting to learn more about CNC programming, and getting to machine the molds myself!

Injection Molding and the Final Product!

Description and more photos to come!